Home » CAM module

CAM

MODULE

Data transmission and information storage

CAM

MODULE

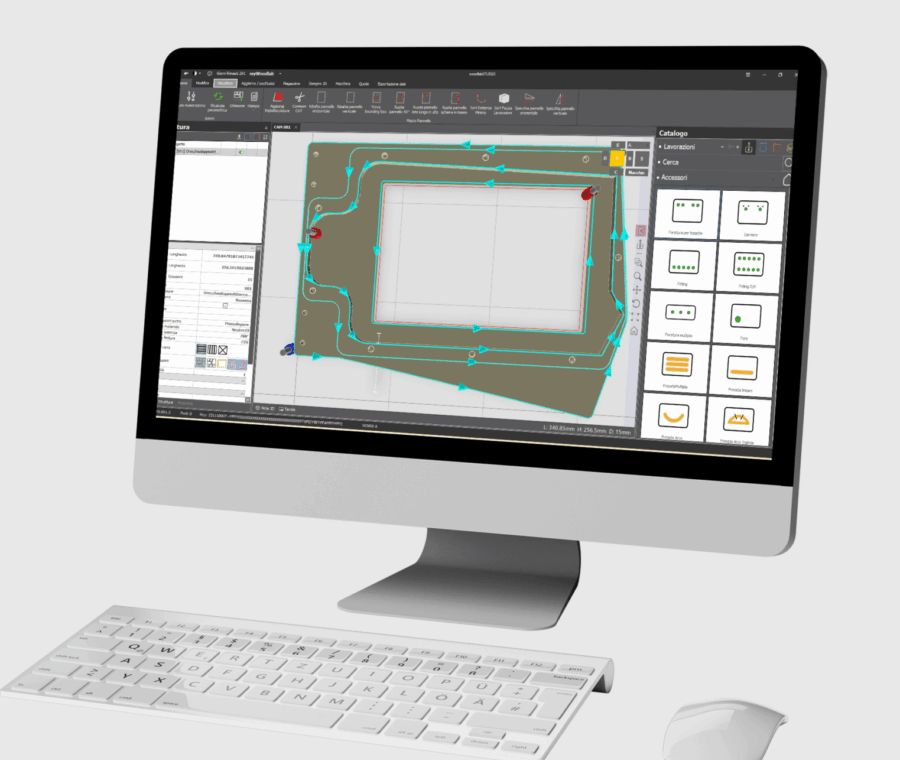

The Woodlab® CAM module calculates and optimises machining operations, transforming technical drawings of individual pieces into precise machine commands.

CAM manages the combination of machining operations and tools available on the machine, generating the correct machining paths based on the set-up.

The entire process is integrated into the same environment: from importing drawings to optimising machining operations and generating machine commands, without the need for external manual intervention.

Who it is for

Woodlab® CAM is ideal for designers and furniture manufacturers who want to optimise production and reduce working times.

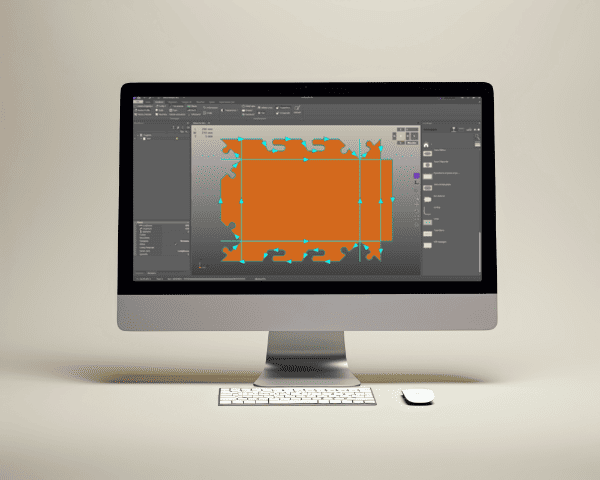

AUTOMATIC

The CAM module translates processes into machine commands without manual intervention, managing tools, paths and optimisations based on the existing configuration.

INTEGRATED

The CAM module is part of Woodlab® STUDIO

and shares data with all other modules

for quick transition.

PARAMETRIC

The CAM module recognises constraints and relationships between elements: if you change a measurement, everything is automatically updated.

INTUITIVE

The CAM module interprets the design like an operator: it recognises a line as a milling operation,

a circle as a hole, and automatically assigns

the right machining operations

without having to redefine them.